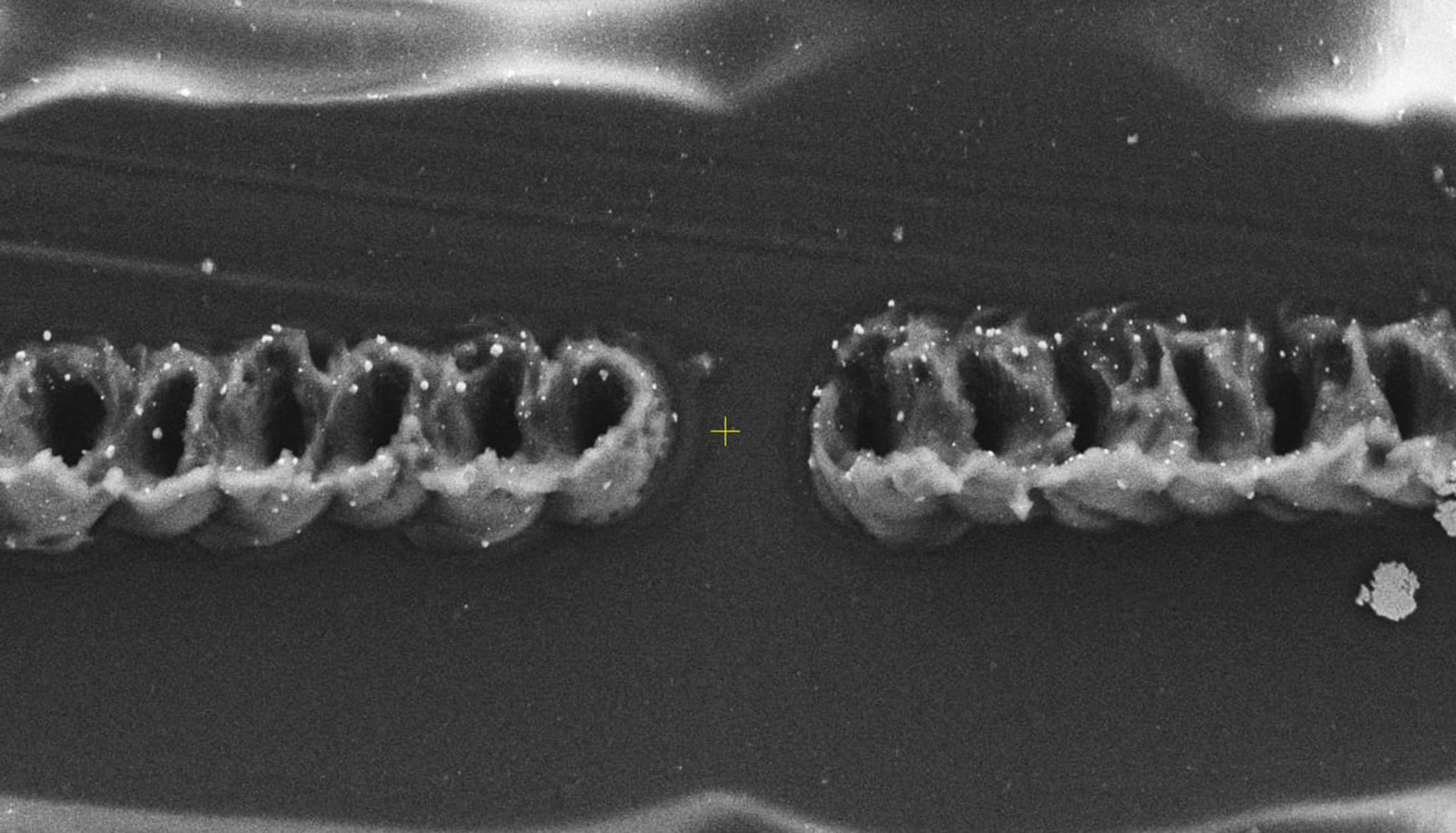

A scanning electron microscope image shows two traces of laser-induced graphene on a polyimide film. View the original image . (Credit: Tour Group/Rice)

Little beam on a microscope makes laser-induced graphene

A new approach (and a smaller laser) lets scientists shrink laser-induced graphene for flexible electronics.

Scientists are using a very small visible beam to burn laser-induced graphene, a foamy form of carbon, into microscopic patterns.

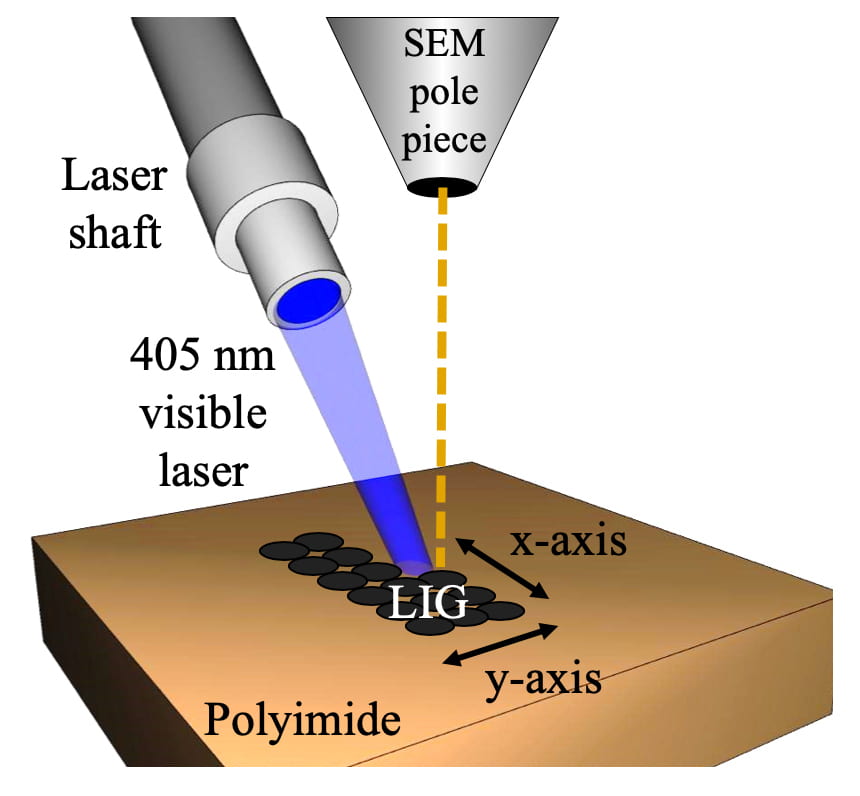

The labs of Rice University chemist James Tour, which discovered the original method to turn a common polymer into graphene in 2014, and Tennessee/Oak Ridge National Laboratory materials scientist Philip Rack revealed they can now watch the conductive material form as it makes small traces of LIG in a scanning electron microscope (SEM).

The altered process, which appears in ACS Applied Materials & Interfaces, creates LIG with features more than 60% smaller than the macro version and almost 10 times smaller than typically achieved with the former infrared laser.

Lower-powered lasers also make the process less expensive, Tour says. That could lead to wider commercial production of flexible electronics and sensors.

“A key for electronics applications is to make smaller structures so that one could have a higher density, or more devices per unit area,” Tour says. “This method allows us to make structures that are 10 times denser than we formerly made.”

To prove the concept, the lab made flexible humidity sensors that are invisible to the naked eye and directly fabricated on polyimide, a commercial polymer. The devices were able to sense human breath with a response time of 250 milliseconds.

“This is much faster than the sampling rate for most commercial humidity sensors and enables the monitoring of rapid local humidity changes that can be caused by breathing,” says lead author Michael Stanford, a postdoctoral researcher at Rice.

The smaller lasers pump light at a wavelength of 405 nanometers, in the blue-violet part of the spectrum. These are less powerful than the industrial lasers the Tour Group and others around the world are using to burn graphene into plastic, paper, wood, and even food.

The SEM-mounted laser burns only the top five microns of the polymer, writing graphene features as small as 12 microns. (A human hair, by comparison, is 30 to 100 microns wide.)

“The LIG features we were creating were so small that they would have been next to impossible to find if we were to lase the patterns and then search for them in the microscope later,” says Stanford, who used advanced equipment at Oak Ridge National Laboratory.

Tour, whose group recently introduced flash graphene to instantly turn trash and food waste into the valuable material, says the new LIG process offers a new path toward writing electronic circuits into flexible substrates like clothing.

“While the flash process will produce tons of graphene, the LIG process will allow graphene to be directly synthesized for precise electronics applications on surfaces,” says Tour, chair in chemistry and professor of computer science and of materials science and nanoengineering.

Coauthors of the paper are from UT Knoxville and Oak Ridge National Laboratory.

The Air Force Office of Scientific Research and the US Department of Energy supported the research.

Source: Rice University

The post Little beam on a microscope makes laser-induced graphene appeared first on Futurity.

Share this article:

This article uses material from the Futurity article, and is licenced under a CC BY-SA 4.0 International License. Images, videos and audio are available under their respective licenses.

Related Articles:

Graphene and germ combo paves way for futuristic tech

July 11, 2019 • futurityGraphene barrier creates mosquito-proof fabric

Sept. 5, 2019 • futurityLinks/images:

- http://dx.doi.org/10.1021/acsami.0c01377

- https://www.futurity.org/wood-graphene-supercapacitor-1500392-2/

- https://www.futurity.org/graphene-electronics-food-nanotechnology-1679232-2/

- https://news.rice.edu/2020/02/12/graphene-forms-under-microscopes-eye/

- https://www.futurity.org/laser-induced-graphene-lig-microscope-2290012-2/

- https://www.futurity.org